Why do alumina dust collectors use metal filter bags?

- Share

- Issue Time

- Mar 24,2020

FOREWORD

Countries in the 21st century are paying moreand more attention to environmental issues. With the advancement of science inthe world today, people's awareness of environmental protection has increased,and the concept of environmental governance has shifted from end governance tosource governance. In the industrial production of chemical industry, petroleumindustry, metallurgy industry, electric power industry and other industrialproduction, high-temperature dust-containing gas, such as chemical synthesisraw material gas, furnace kiln gas, reactor scorch and coal combustionhigh-temperature flue gas, All of these high-temperature dust-containing gasesneed to be dust-removed and gas-solid separated at high temperatures. Finally,it guarantees high efficiency, low energy consumption, and reduced emissionsfor industrial development, achieving energy saving, environmental protection,and reducing dust and equipment wear.

Introduction

The traditional high-temperature dust removalmethod is to process high-temperature gas into a non-metal filter bag afterbeing processed by a cooling system. The gas temperature needs to be loweredbelow 200 ° C to reach the temperature range that the filter bag can withstand.Solid particles in the gas are removed and finally discharged.

The advantages are:lower cost.

Disadvantages are:low temperature resistance, waste of thermal energy, long filter processingtime, low efficiency, easy to burn bags in high temperature processing, andhigh frequency of filter bag replacement. (Usually need to be replaced everytwo years)

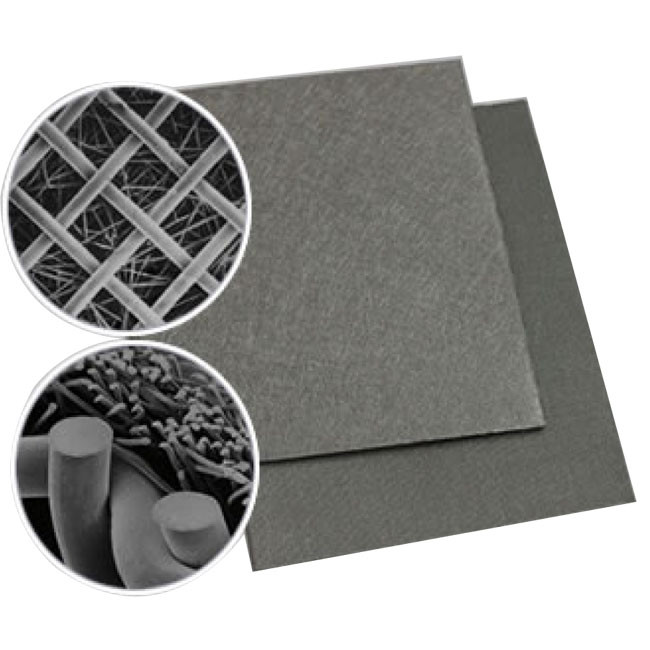

The high-temperature dust-removing metalfilter bag produced by our company is made of stainless steel sintered felt,which overcomes the shortcomings of traditional filter bags, such as hightemperature resistance, difficult regeneration, low strength, and poor wearresistance. The stainless steel fiber sintered felt is made of extremely finestainless steel fibers (accurate to the diameter in micrometers), woven andlaminated, and sintered at high temperature. The finished felt has a poregradient formed by different pore layers, which can be controlled to obtainextremely high filtration accuracy and greater dirt holding capacity. It hasthe characteristics of three-dimensional pore shape, porous structure, highporosity, and uniform pore size distribution.

The company's high-temperature dust removalmetal filter bags have been applied to nearly 20 industries in China: Shandongalumina enterprises, Shanxi calcium carbide enterprises, Inner Mongolia coalenterprises, Henan chemical enterprises, Shaanxi cement enterprises, Guangxipower plant enterprises, Yunnan natural gas enterprises, etc.

Our company is the draftingunit of the Chinese national standard for this material. The standard number is"Stainless Steel Fiber Sintered Felt" GB / T20100-2016, and it hasmore than ten related dust removal patents.

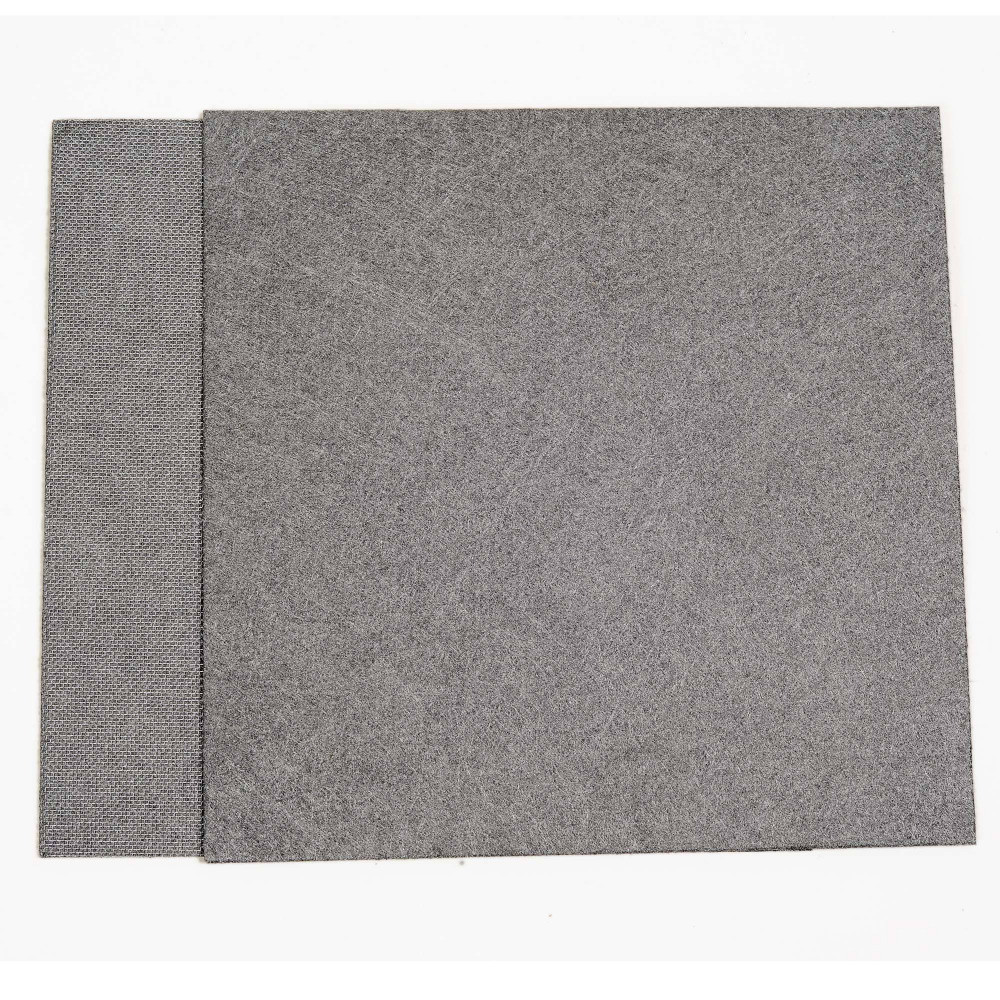

Product Image:

Stainless steel fibersintered felt

The rawmaterials for making high-temperature dust collectors have the followingadvantages: 1. Large dirt holding capacity, high filtration accuracy, anduniform and stable porosity. 2. High temperature and corrosion resistance,acid, alkali, organic solvent, medicine and other corrosion resistance, can beused in a long-term environment at 450 ℃. 3. Easy processing, forming and welding.

Product relatedtechnical parameters can refer to the following standards:

1. The production ofsintered felt is performed in accordance with GB / T20100-2016 stainless steelfiber sintered felt.

2. Filtrationaccuracy and determination of dirt holding capacity shall be determined inaccordance with GB / T18853-2002.

3. The measurement ofbubble point pressure shall be carried out according to the regulations in GB /T5249.

4. The airpermeability shall be measured according to the regulations in GB / T5453, thepressure difference shall be 200pa, and the medium shall be air.

5. The determinationof the breaking strength shall be carried out according to the regulations inGB / T228.

Stainless steelsintered felt high temperature dust collector

Thesignificant advantages of the product are: 1. The gas is directly filtered andthe process is simple. 2. Good air permeability, uniform and stable accuracy.3. Good regeneration performance, fast regeneration speed, convenientinstallation, high efficiency and long service life. 4. Easy can be made ofother special materials, such as Hastelloy, nickel mesh, 310S, etc.

The stainless steel metal filter bag is madeof micron-grade stainless steel metal fiber as a raw material and is laid by anon-woven laying process. It is made of mixed stainless steel metal fibers withdifferent wire diameters. This material has excellent temperature resistance,chemical resistance, Low running resistance and long service life. After hightemperature vacuum sintering and calender treatment, its surface is madeSmooth, because of the gradient structure of fibers with different wirediameters, it makes surface filtration on the filtering surface, which helpsprevent fine dust from penetrating into the deep layer of the filter material,and further optimizes the ash cleaning performance of the filter material.

Product technicaladvantages-"surface filter structure" as shown below

"Surface Filter Structure"Structure

Through the reasonable combination ofstainless steel fibers with different diameter, the product has a clearcomparison of the smoothness of the two sides of the filter material (that is,the pore size of the two sides of the filter material is different). Capabilityto reduce the difficulty of cleaning the filter material, while reducing theresistance of the dust collector.

Product technicaladvantages-high temperature vacuum sintering molding technology

The stainless steel metal filter elementadopts vacuum hot pressing forming technology, and the fibers are firmlybonded, which reduces the occurrence of fiber shedding and bag breakage, andextends the service life of the filter bag.

Product processing refers to relevanttechnical parameters. Product processing is controlled according to thefollowing documents, materials, procedures and specifications for variousprocesses and production quality

1. "Steel pipe flange (PN series)"HG / T 20592-2009

2. "Steel butt-welded seamless pipefittings" GB / T 12459-2005

3. 《Tungsten TIG Welding Technology OperationRules》QB 201.1-2008

4. "Sintered felt filter testoutline" XL / JS-SY-ZSL-001

5. 《Stainless steel fiber sintered filter felt》GB / T 20100-2016

6. "Technical Requirements for Bag DustCollector" GB / T 6719-2009

7. "Technical requirements for environmentalprotection products, filter materials for bag filters" HJ / T 324-2006

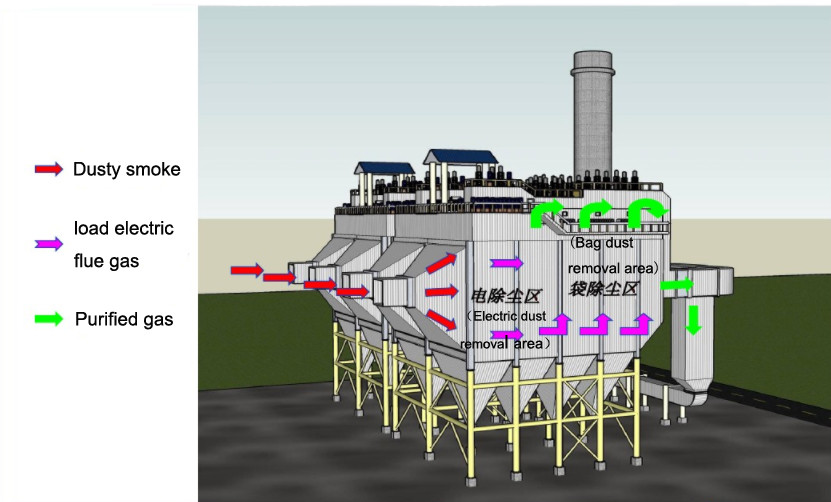

Customer use cases are as follows:

Pic1:Filtrationmechanism

Pic1:Filtrationmechanism

Pic 2: installationscene