Pharmacy Industry

- Share

Standard Five-Layer Sintered Mesh Pharmacy Industry Application

Standard Five-Layer Sintered Mesh Introduction

Standard sintered five-layer mesh consists of the protective layer, the filter layer, the dispersion layer, and two reinforcing layers. It provides excellent performance such as uniform and stable precision and high strength, so it is ideal filter medium for applications requiring high compressive strength and uniform filtering particle.

Thanks to its surface filtration construction and smooth aperture duct, it is good at backwashing and regeneration, therefore, it can be used for a long time , and is especially suitable for continuous and automatic operation, which exceeds any other kind of filter material.

Furthermore, this sintered mesh is easy to be formed, machined and welded. It can be produced into many kinds of shapes such as circular, cartridge, cone and pleats.

1.Chromatography Equipment

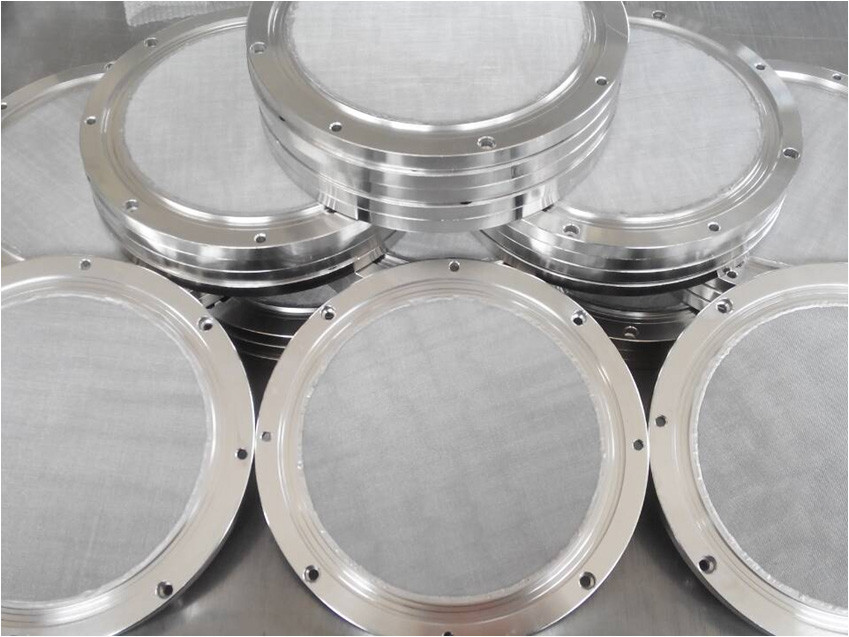

The application of the standard five-layer sintered mesh on the chromatographic equipment is very mature. Most of them are disc-shaped and directly fixed between the flanges and sealed with a gasket. The sintered mesh discs are directly welded to the flanges and then fixed. Various forms.

Function: used in chromatography equipment, silicone, activated carbon, alumina, ion exchange resin, ion exchange fiber, etc., used to purify liquid materials, or adsorb unwanted or harmful components, or adsorb useful components, and finally achieve purification.

The sintered mesh serves to support the smooth passage of the fine powder particles and the liquid material to be purified.

The sintered mesh serves to support the smooth passage of the fine powder particles and the liquid material to be purified.

The sintered mesh is mostly in the form of a disk with a thickness of 1.7 mm; the precision is mostly 150 mesh, 200 mesh, and 400 mesh.

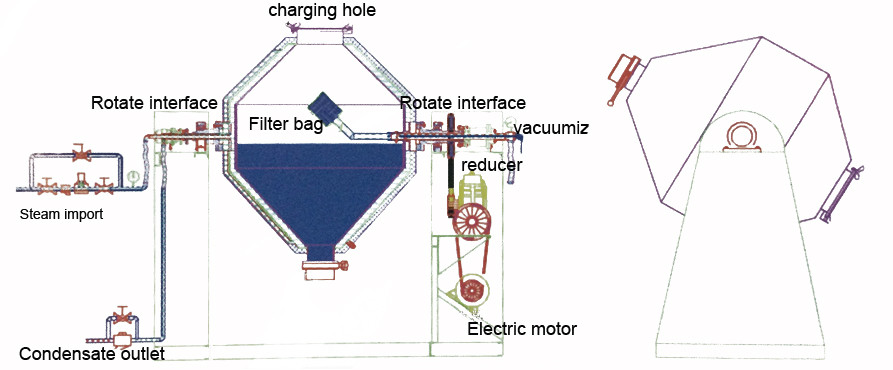

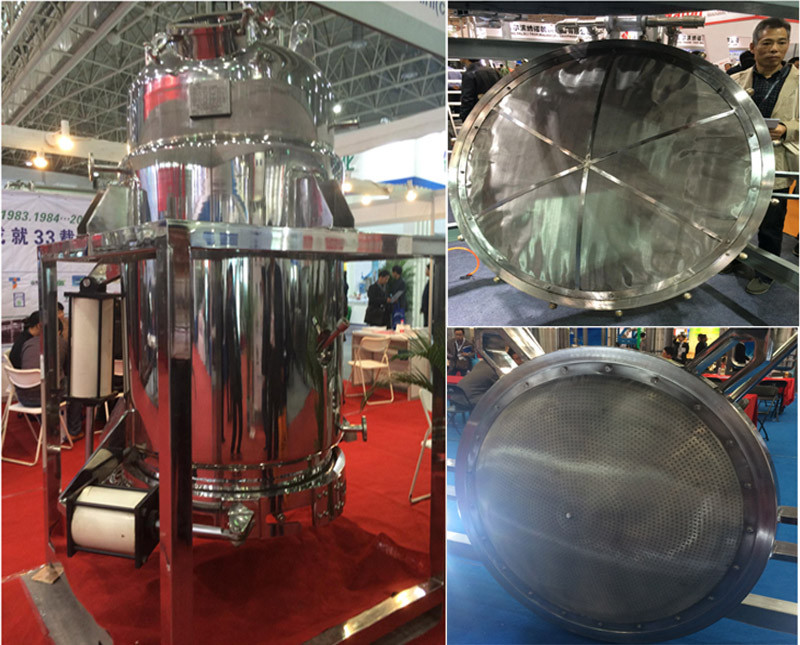

Double Cone Rotary Vacuum Dryer

Double cone rotating vacuum drying machine is suitable for chemical, pharmaceutical, food industries such as powder, powder, and the concentration of fibrous materials, mixing, drying and needs low temperature drying of materials (such as biological products, etc.), more applicable to the easy oxidation, volatile, heat-sensitive intense stimulation, toxic materials, and are not allowed to destroy the crystal materials and dry.

The function of sintering net: the material needs to be vacuumed in the dryer, and the function of sintering net is to prevent the powder from being removed.

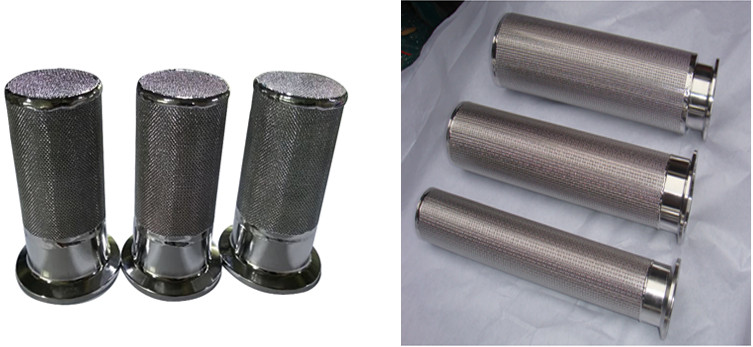

The sintered mesh is made into Fast interface filter cartridge ; the filter is also called a respiratory filter. The thickness is 1.7 mm; the precision is mostly 5 μm.

Six-Layer Sintered Mesh Pharmacy Industry Application:

Six-Layer Sintered Mesh Product Introduction:

Sintered six-layer mesh is composed of six-layer stainless steel wire mesh, which is special sintering in vacuum oven, to create a new filter material with high strength and rigidity. Its interlaced mesh forms a uniform and ideal filtration structure. As a new filter material, it has excellent performances such as high precision and strength,efficient flow restriction, mechanical and resistance to abrasion、heat and cold. It is mainly applied in pharmaceutical and food industry etc., especially in the three-in-one or two-in-one pharmaceutical equipment.

Three-In-One And Two-In-One Filtering Equipment

The three-in-one filtering equipment is a filtering equipment integrating filtration, washing and drying.

The two-in-one filtering equipment has less drying process than the three-in-one filtering equipment. It is a filtering equipment integrating filtration and washing.

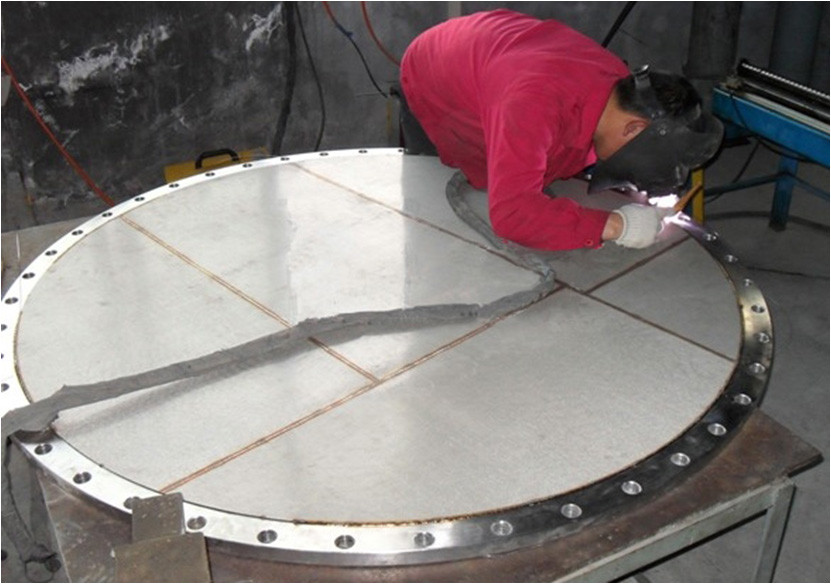

The sintering network plays the role of filtering and supporting materials in the three-in-one and two-in-one filtering equipment. The three-in-one and two-in-one filter plates have high requirements on the sintering network, with uniform pore diameter, flat screen surface and no more than 2mm on a surface with a flatness of 1000x1000.There shall be no pits, foreign matter or pollution on the surface ;No foreign matter should fall off, need to be cleaned thoroughly with ultrasonic wave

The sintered mesh adopts a six-layer sintered plate mesh, that is, the sintered mesh has a thickness of 3.5 mm; the precision is mostly 15 to 25 μm.

Perforated Plate Sintered Mesh Pharmacy Industry Application

Perforated Plate Sintered Mesh Product Introduction:

This is a new filter material, which is sintered together with perforated plate(304 or 316L) and several layers of plain or twilled woven wire mesh, the layer and mesh number is decided by the working condition and application.

Purifying Tank Equipment

The purifying tank is a kind of equipment used for extracting useful materials after the materials are heated in the tank.

After several materials are heated and soaked in the tank and the reaction is completed, the solid materials are intercepted in the tank through the bottom and side filter net, and the liquid flows out into the next process.

The sintered mesh is mostly made of punched plate composite sintered plate mesh, which has the shape of disc, cylinder and cone filter; the thickness of the sintered mesh is 2~6mm; the precision is 150~250μm.