Sintered Iron Chromium Aluminum Fiber Felt

- Price

- US $355-360

- Model

- FeCrAl fiber felt

- MOQ

- 10 piece

Item specifics

- Material

- FeCrAl Fiber

- Application

- Burner

- Fiber Dia

- 22um,60um or other

- Feature

- High Temperature

- Functure

- Non-woven

- Advantage

- Long Service Life

- Usage

- The Infrared Combustion

- Shape

- Customized

- Brand name

- Sany

- OEM Serive

- Accepted

Review

Description

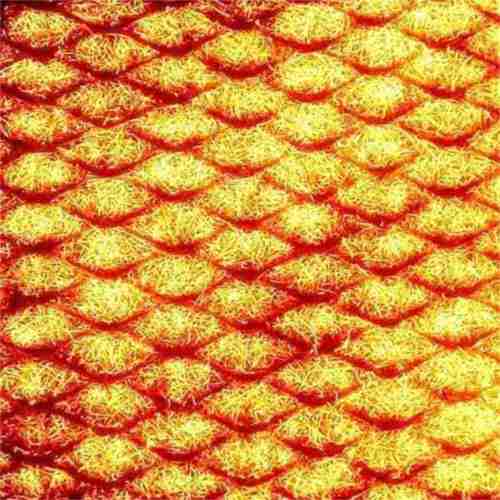

Sany sintered Iron chromium aluminum fiber felt introduction

Sany sintered Iron chromium aluminum(FeCrAl) fibre felt is a kind of metal fiber sintered felt ,with long service life, environmental and energy-saving, high temperature resistance, anti-distortion, no carbon deposit, good toughness, folding and uniform pore size distribution. It has high porosity and environmental carrying capacity

Sany sintered FeCrAl fibre felt is widely applied in many fields,such as automobile tail gas treatment, burner, boiler improvement, gas air conditioning, glass annealing, food baking oven, heater, coating paper and drying industry.

Sany sintered Iron chromium aluminum fiber felt specification

Item | Thickness (mm) | Square meter weight(g) | Fiber dia(micron) |

1 | 0.3 | 460~500 | 22 |

2 | 1.5 | 1600~2000 | 60 |

3 | 2.0 | 2400~2600 | 60 |

4 | 2.5 | 2800~3200 | 60 |

5 | 3.0 | 4200~4400 | 60 |

6 | 3.5 | 4400~4600 | 60 |

Sany sintered Iron chromium aluminum fiber felt type

High temperature dust removal series: sintered FeCrAl dust removal filter cartridge is a kind of new filter material. Compared with non-metallic dust filter bag that the highest heat resistance is less than 300 degrees, stainless steel dust removal filter cartridge not exceed 450 degrees, sintered FeCrAl dust removal filter cartridge is up to 900 degrees. It has excellent filtering effect due to its deep labyrinth structure, and can be applied to steel, electric power, high temperature of waste incineration and other harsh terms.

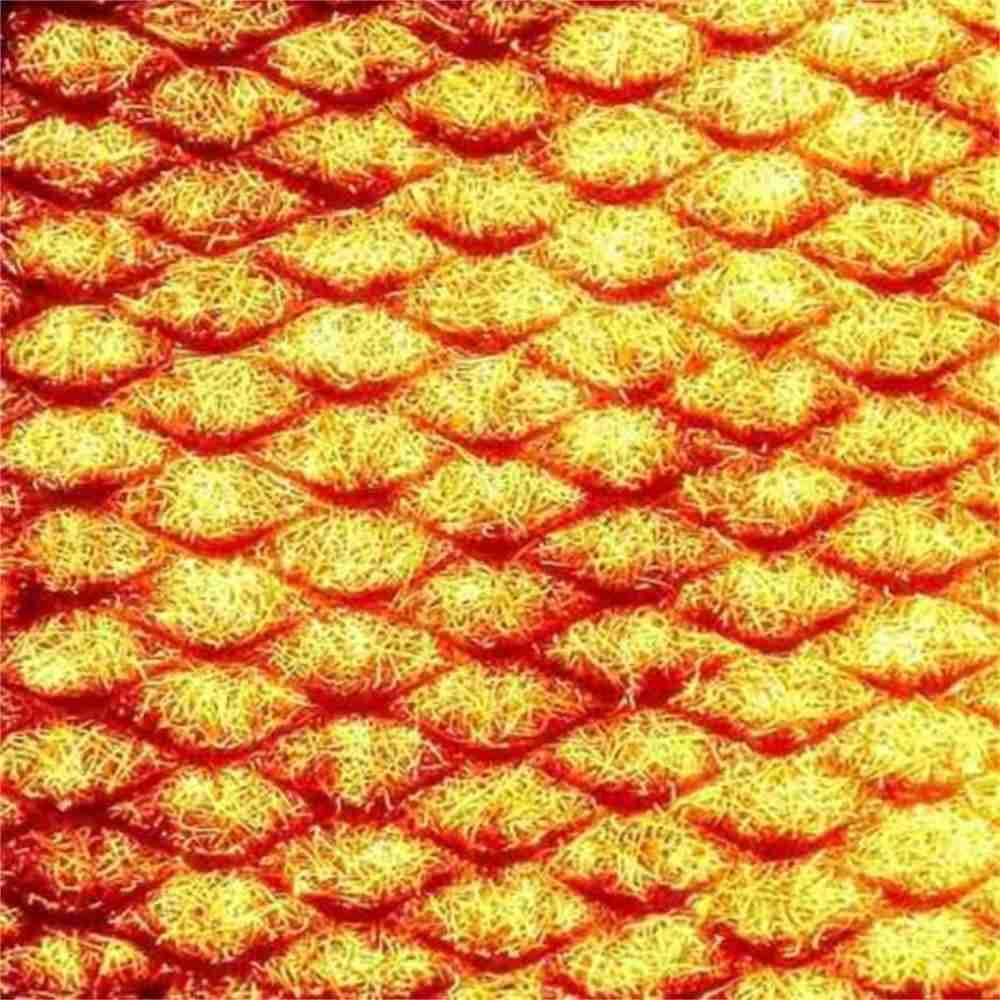

Purification series:sintered FeCrAl fiber felt as purification materials is widely applied in chemical industry and diesel automobile emission devices of the four standard. FeCrAi alloy has porous 3 d mesh structure. It is the best choice of the integral catalyst support material, due to pore size of 0.1 mm and porosity of 85%.

Sany sintered Iron chromium aluminum fibre felt feature

1) high temperature 1100 degrees resistance

2) hot and cold impact ability

3) not bibulous

4) with low thermal inertia

5) complete combustion radiation

6) long service life