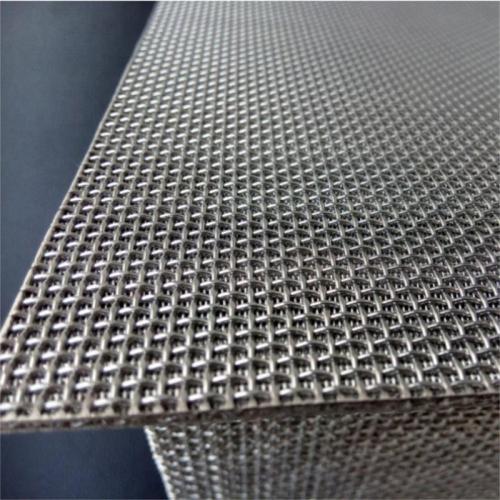

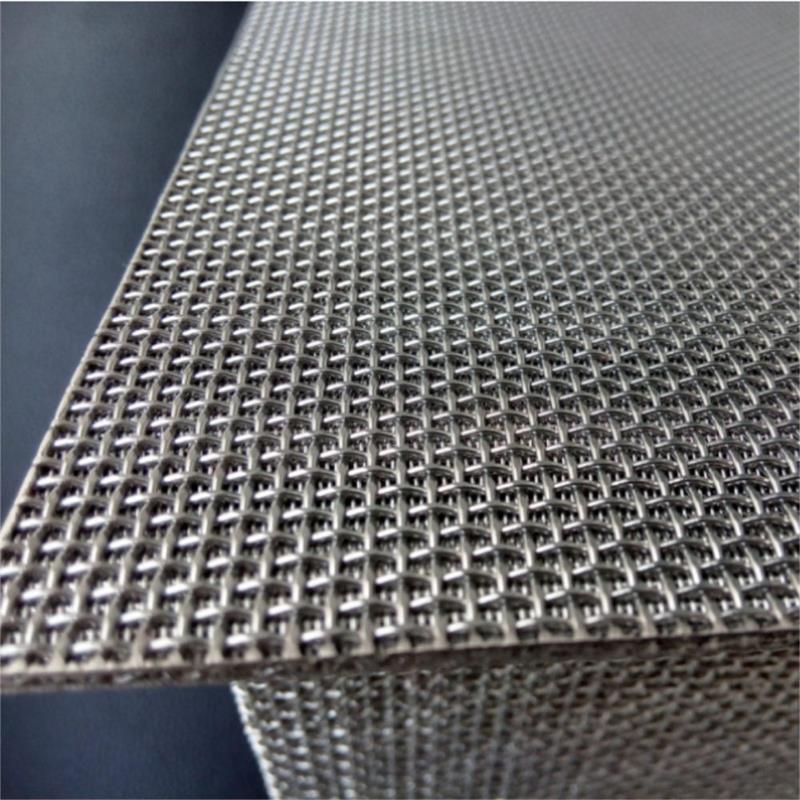

Multi-layer Sintered Woven Wire Mesh

- Price

- US $490-500

- Model

- multi-layer sintered mesh

- MOQ

- 1 square meter

Item specifics

- Material

- Stainless steel woven wire mesh

- Thickness

- Designed

- Application

- Industry

- Technicue

- Sinter,Woven

- Certificate

- ISO9001

- Structure

- Customized

- MOQ

- 1

- Free

- According to size

- Brand name

- Sany

- Product name

- Multi-layer sintered woven wire mesh

Review

Description

Sany multi-layer sintered mesh introduction

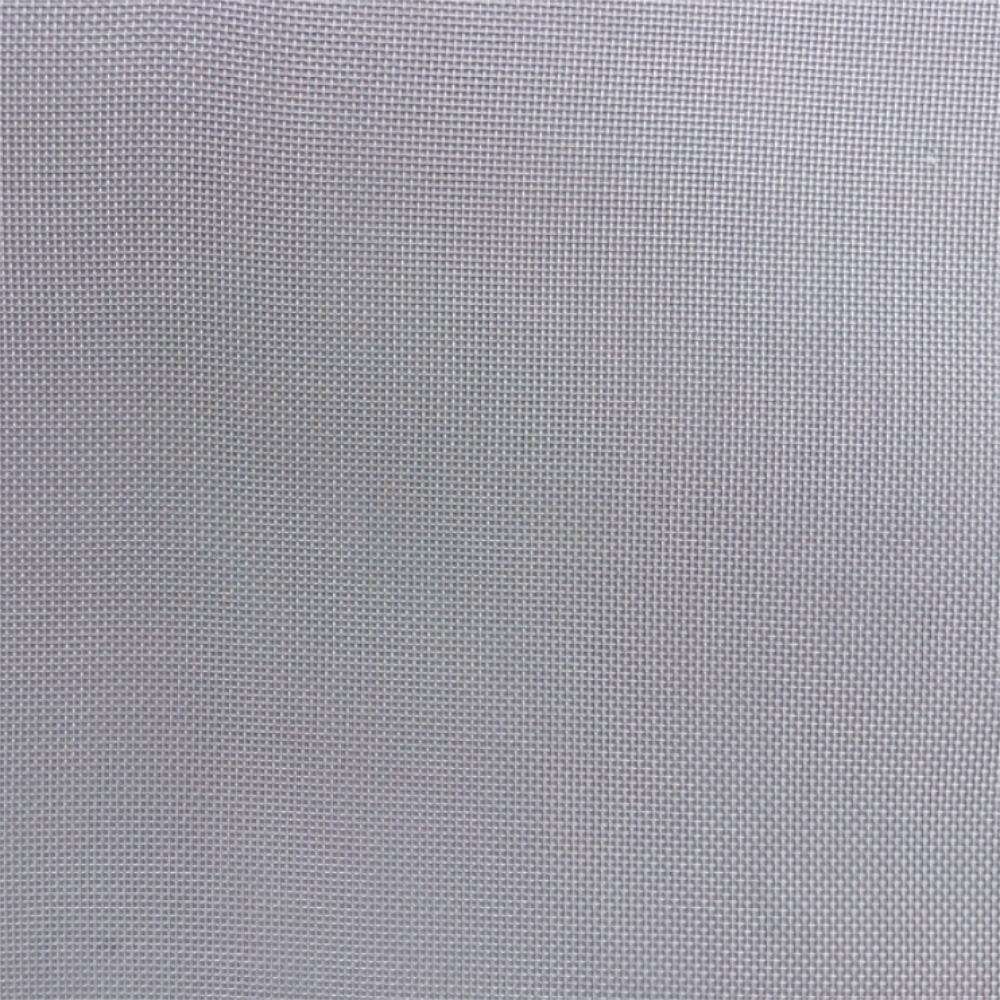

Sany multi-layer sintered woven mesh is composed of multi-layer stainless steel wire mesh(maybe 3-layer,4-layer,7-layer,8-layer,10-layer, etc.), which is special canlendering and sintering in vacuum oven, to create a new filter material with high strength and rigidity. Its interlaced mesh forms a uniform and ideal filtration structure. It is widely used in many industries such as the petrochemical,nuclear power, synthetic fiber, film, food, pharmaceutical, aerospace and environment protection industry.

Sany multi-layer sintered mesh technical parameters

Product Name | Sany multi-layer Sintered Woven Wire Mesh |

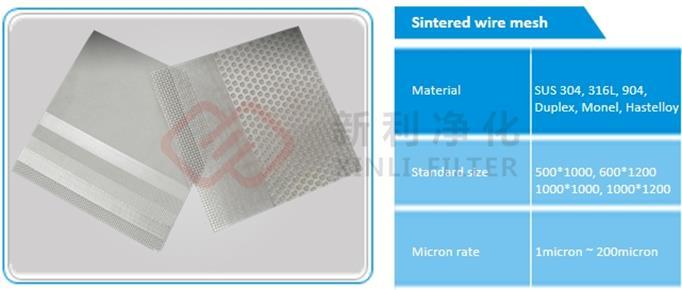

Material | 304 or 316L Stainless steel wire mesh.But special material can be selected as well (such as Hastelloy, Monel, 904L etc.). |

Micron Rate | From 1um to 300um, optional. |

Standard Size | 20''×40'' 40''×40'' 40''×48''. Max size is 48''×60'' (1''=25mm) |

Thickness | According to the number of mesh layers |

Shape | Round,Square,Ring,Oval,Bowl,Tube,Cone etc. |

Operating Temperature | -200~600℃ |

Feature | High strength and rigidity,Uniform and stable precision,Cleanable |

Sany multi-layer sintered woven mesh main application

1.Distribution and cooling material in high temperature;

2.Material used for gas distribution and fluidization bed;

3.Material requiring high precision, stable performance in high temperature;

4.High pressure backwashed oil filter;

Sany multi-layer sintered woven mesh application projects

1.Hydraulic oil & lubricant oil filtration in machinary industry;

2.All kinds of polymer filtration in chemical fiber film industry, filtration in high temperature and for corrosive liquid,material filtering, cleaning and drying in pharmacuetical industry;

3.Gas distribution in powder industry,fluidization in steel industry;

4.Buzzer for explosion proof electric apparatus;