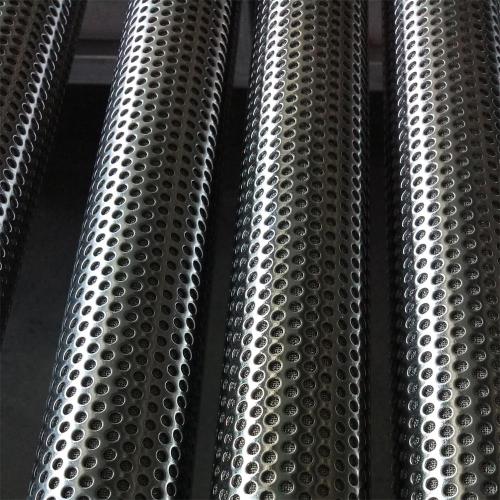

Sintered Stainless Steel Perforated Mesh Filter Element

- Price

- US $190-200

- Model

- perforated mesh filter element

- MOQ

- 1 piece

Item specifics

- Material

- SS Sintered Perforated Pipe With Wire Mesh

- Application

- Industrial Filtration

- Mesh Hole Size

- 2um-500um

- Feature

- Washable and Reusable

- Advantage

- Resistant to High Temperature & Corrosive

- Certification

- ISO9001

- Size

- Customizable

- Brand Name

- Sany

- OEM

- Yes

- MOQ

- 1 pcs

Review

Description

Sany sintered stainless steel perforated pipe filter element introduction

Filter cartridge for water treatment equipment is made of perforated plate and wire mesh sintered together, of which is layer number and mesh number are designed to according to the using condition and application.As it is intergrated by sintering pressure-resistant framework and filter mesh together,thus it has higher rigidity, more excellent back-wash efficiency,smaller pressure drop loss etc. And thus is widely used in automatic water filter equipment,intelligent differential pressure type water treatment equipment and food&beverage filter equipment etc.

Sany sintered stainless steel perforated pipe filter element technical parameters

Name | Sintered Perforated Pipe with Wire Mesh Filter element |

Material | SS304 / SS316L |

Micron Rate | 2-500µm |

Pressure Range | 1.5-3MPa |

Max Temperature | 600℃ |

Certification | ISO9001 |

Feature | Higher mechanical strength, Better backwash efficiency, Lower pressure drop loss |

Application | Water treatment, Beverage, Food, Metallurgy, Chemical and Pharmaceutical |

Advantage

Wear-resistant, high strength and long service life, unity-structure, not curly, easy to use, acid-resistant , alkali-resistant, corrosion-resistant,heat-resistant

How to Use

Wire mesh filter element can be reused. It should be removed, cleaned and reinstalled at scheduled intervals or when it becomes dirty. Replace it with new elements when the currently one cannot be properly cleaned or is damaged.