Metal fiber filter bag used for Alumina Oxide industry

- Price

- US $92-100

- Model

- Metal Fiber Type

- MOQ

- 1 piece

Item specifics

- High temperature resistance

- 900 ℃

- High wind speed

- ≥1 m/min

- Emission concentration

- 5mg / Nm3

- Size

- Customized

Review

Description

Metal fiber filter bag used for Alumina Oxide industry

Introduction

It is made of metal fibers with a micron diameter through non-woven laying, stacking, and high-temperature sintering, and then rolled and welded. The main materials are stainless steel 316L, stainless steel 310S, iron chromium aluminum alloy, etc.

Effectively avoids the disadvantages of non-woven filter bags that are not resistant to high temperature, ceramic filter elements and sintered powder elements are brittle.

Feature

1. High temperature resistance (<900 ℃), strong thermal shock resistance, corrosion resistance,

high strength

2. High interception efficiency, emission concentration can be lower than 5mg / Nm3

3. Good air permeability, reduced initial pressure, low energy consumption

4. Handling high wind speed (≥1 m/min)

5. Online backflush and offline cleaning, good regeneration effect

6. Long working life: no clogging

7. Conductive to avoid dust explosion caused by static electricity

8. The filter material is resistant to high temperatures and can effectively prevent bag burning

9. Easy to recycle and avoid secondary pollution

10. Dust removal system volume and footprint can be significantly reduced

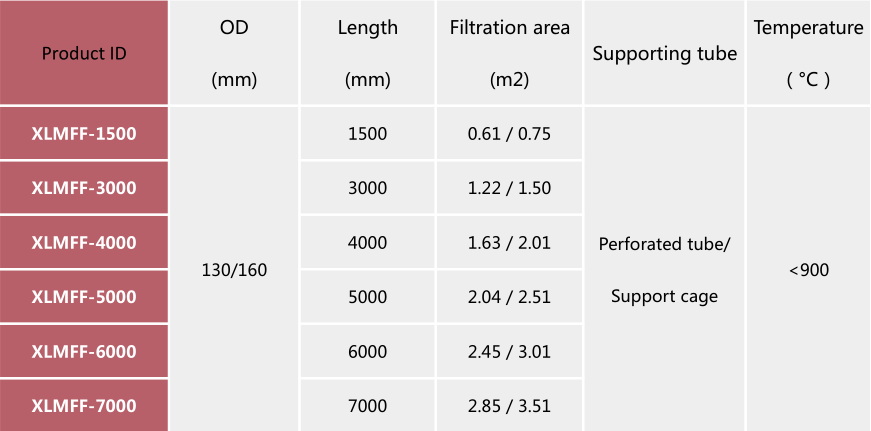

Technical parameters

Application

1. Hot gas filtration during the production of Magnesium Oxide, Alumina

2. Catalyst or precious metal recovery in gas processes

3. Power、Steel、Cement、Glass、Chemical、Metallurgical Industry

4. Biomass energy

5. Other