Stainless Steel Composite Mesh Tube For Protecting Valves Filter

- Price

- US $46-50

- Model

- Sintered wire mesh

- MOQ

- 1 piece

Item specifics

- Product name

- Stainless Steel Composite Mesh Tube For Protecting

- Certificate

- ISO9001

- Color

- Silver

- Mesh count

- 1-635 Mesh

- Feature

- Corrosion Resistance

- Application

- Industry Filter

- Filter rating

- 1-300um

- Sample

- According to size

- OEM service

- Accept

- PH

- 1-14

Review

Description

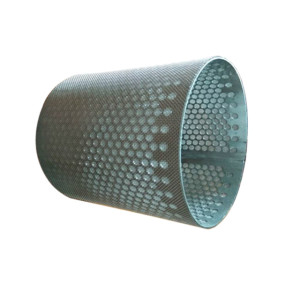

Stainless Steel Composite Mesh Tube For Protecting Valves Filter product introduction:

The compressor had reliability issues with the valves failing within months. The objective for the valve change is to improving compressor efficiency. The picture shows the cages for the suction and discharge valves, with new Valve Protection Mesh used in the suction valve cage.

Stainless Steel Composite Mesh Tube For Protecting Valves Filter Product Image:

Stainless Steel Composite Mesh Tube For Protecting Valves Filter Product Characters:

Why Choose Sintered Wire Mesh:

1.High strength and rigidity :

extreme mechanical strength and pressuretolerance, can be machined, welded and assembled,

2.Uniform and stable precision:

consistent filter property in various media,without apertures changing during operation.

3.Widely service environment:

can be continuously in temperature rangingfrom-200℃ to 600℃ and filtering in acid and alkali conditions.

4.Cleanable:

backwash easily, and reused with longerservice span, and can be cleaned by means of ways, such as backstream,filtration liquid, ultrasonic, dissolution and baking.